by Tim Hoeffel, Better Painting & Coatings

Reprinted from the July 2021 edition of Property Management Quarterly published by the Colorado Real Estate Journal, expanded edition

Traditional building concepts are getting challenged

Build it tight, ventilate right. This mantra is used with new construction when energy efficiency is a goal. This is not true of most of the existing buildings in America.

Our understanding of building science and resultant codes has evolved over time. We used to think buildings needed to “breathe,” but now we know that’s not true. An airtight cool building reduces operating expenses, increases value and desirability.

What has been missing until now is a reasonable cost effective method to upgrade our existing buildings. I would like to suggest insulation coatings, aka cool building coatings, as a continuous heat, air, moisture and weather barrier for the exterior and interior of buildings. The easy way to keep buildings cool is to not let them get hot.

Insulation coatings block heat, save energy

Air handlers move heat, insulation stores heat; now insulation coatings can block heat.

Used correctly, insulation coatings keep a building’s enclosure cool, dry and air free, allowing the building to work closer to as intended. Cool preserves and heat deteriorates.

A study by Concordia University researchers in Montreal, published in Energy and Buildings confirms that, contrary to the belief that cool roofs won’t work in colder climates, they actually provide net energy — and monetary — savings.

“Using a cool roof on a commercial building in cold climates is typically not suggested based on the presumption that the heating penalties may be higher than the cooling savings,” says Hashem Akbari, professor in the Department of Building, Civil and Environmental Engineering and the study’s senior author.

“Our research shows that any improvement to a roof that limits the summertime solar heat gain actually results in energy-cost savings for the building owner, as well as a reduction in the building’s overall environmental impact.”

One of the reasons this is so effective is because it reduces thermal bridging. A thermal bridge is a part of the wall or roof that goes directly from exterior to interior (or vis-a-versa) without anything slowing down the heat movement. The heat travels across the bridges and decreases performance by about 15%.

Heat reduction is important, but it doesn’t work alone. It works in conjunction with air and moisture. Air is the main mover of heat, moisture and even sound. Sealing the enclosure by reducing air leaks becomes a crucial task. Doors and windows are the main culprits, but don’t forget outlets, switches, pipes, vents and transitions between floors and ceiling.

In 2014, air leaks accounted for 55% more natural gas usage and 28% more electricity use in commercial buildings in cool climates while meeting air barrier requirements. Potential savings of $3,000 to $3,500 per year in utility bill costs.

If you have an older building built before insulation and/or air barrier codes, there is a good chance there is diffusion through the walls, according to Oak Ridge National Labs. This could add an extra 25% to energy costs.

Reaching all these areas can be difficult and time consuming (expensive). A simple way of reducing heat movement through conduction, convection and radiation is with a cool insulation coating, like my flagship coating. A semi-permeable resin hits the “just right” zone of tight enough but not too tight.

A cool savings story for cool insulation coatings, Denver, CO

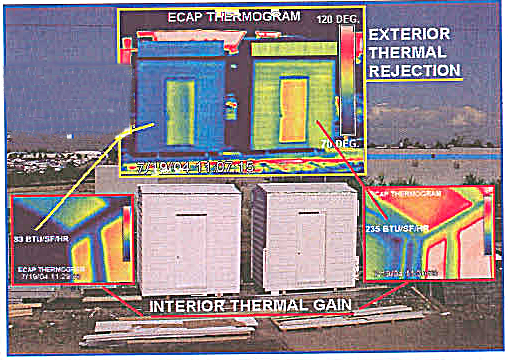

In July 2004, a mostly sunny day in Denver, two identical test sheds were built. One was painted with typical white reflective paint and the other with an insulation coating. The third party conducting the test was the state of Florida Energy Office/Energy Conservation Assistance Programs.

It used a method for “comparing utility loads in standard constructed buildings.” The objective of this analysis was to determine the impact of the as-built conditions and as-installed components/equipment on the utility loads in occupied buildings.

The results were:

In every instance, the field test results concur with the manufacturer’s published data on the product’s anticipated performance curves obtained using in-laboratory test methods.

In every instance, the building coated with the heat-block coating product enhanced the performance of standard insulation products.

These performance enhancement properties were found to be equally effective on both roof and side wall applications.

The differences created by the insulation coating product concerning load reductions produced by thermal conduction, convection and absorption were significant. Additionally, significant reductions in moisture infiltration also were noted.

Some 1,037 British thermal units was reduced to 766 BTUs, 26% to 30%, to maintain the same comfort level, depending on levels of direct sun light (solar gain).

A cooler coating for Colorado Springs roofs and walls

Reflective coatings reflect visible and ultraviolet light, which carry about 47% of the sun’s heat. Infrared light carries the remaining 53% of solar heat. This long wave part of the spectrum is where an insulation coating excels. The Department of Energy’s Building Technology Office is looking for solutions to the IR problem. Depending on the product, 30% – 99% of the IR spectrum can be blocked.

Some manufacturers use IR reflective pigments, while others use special types of ceramics. IR reflective pigments allow “cool colors.” These pigments repel about 30% more IR light than normal pigments and keep a wall about 30% cooler than standard colorants.

The ceramic-based coatings tend to be more effective. The ceramics normally come in micro and nano sized particles with a hollow vacuum in the center. As we know from insulation, it’s the dead air spaces that provide the best insulating qualities. There are case studies showing results from 30% to 70% reduction in roof temperatures over long periods.

My flagship coating combines IR blocking, visible light and UV blocking for a total of 96% blocking of the total solar spectrum in a tintable base that is more effective than IR pigments alone.

Intermodal Steel Building Unit Association (this is the Association for building construction using shipping containers) has concluded just buying cenosphere (ceramic) powder DOES NOT make a proper Ceramic paint insulation. It is somewhat effective but ultimately disappointing. It truly requires a special mix of the cenospheres and certain proportions of other ingredients. The four (4) ceramics claim is actually valid with most ceramic coating manufacturers who use high quality cenospheres.

Insulation that doesn’t insulate?

Insulation coatings do not work the same as traditional insulation. They don’t meet the definition of insulation because that requires a minimum of 1-inch thickness. Coatings are said to add insulation “value” when used correctly. They reduce the temperature gap between the exterior and the interior of your building. They don’t hold heat, just reduce penetration when it’s present.

Reducing the delta T from a hypothetical 130 degrees Fahrenheit on the exterior wall to 75 F on an interior wall, a 55-degree difference, to closer to 90 F exterior wall temperature, a 15-degree difference, greatly reduces the amount and speed at which heat moves through the enclosure.

Lowering the daytime heat inside the walls also reduces convection loops in batt insulation. Convection loops (air movement) lower the insulation’s effectiveness. Storing less heat in the insulation means the air conditioning turns off more often. And reducing the amount of humidity moving through the enclosure means less dehumidification. Condensation, especially in the roof assembly, can be avoided using proper design techniques.

Interior use is primarily for the ceiling. Since most of the heat collects at the ceiling, having a heat resistant barrier there would make sense. They are best used in an open ceiling or drywall ceiling configuration. There are also solutions for window tint coatings that can reduce the indoor temperature 3-5 degrees.

These cool building coatings increase profits with tenant comfort levels and productivity and lower the carbon footprint. Higher energy efficiency may qualify you for higher lease rates and asset valuation. Services are normally written off in the same year. Getting a better return on your investment could be as simple as switching to a cool insulation coating instead of the same old, same old paint or roof coating.

About the author

Better Painting & Coatings is a full service coatings contractor specializing in cool insulation coatings to help building and business owners save money, increase tenant satisfaction and reduce pollution. Coatings for roof, walls and window tint, along with assessment testing and remediation, create a complete enclosure solution for energy cost reduction. Talk to Tim Hoeffel at 719-641-5043 or email to [email protected] to see how you can start lowering energy use.